This article is built around how professional kitchens actually stay under control on a daily basis. Instead of generic “to-do” lists, it breaks down the critical daily management checks that experienced kitchen leaders use to protect food safety, consistency, labor efficiency, and margins—before, during, and after service. The goal isn’t perfection; it’s creating daily discipline so problems are caught early and the kitchen runs predictably, even on the hardest shifts.

TL;DR Quick Answers

restaurant kitchen management

Restaurant kitchen management is the daily system of checks and controls that keep food quality, safety, staff execution, and costs consistent. It relies on routines and verification—not memory—so the kitchen runs predictably even on busy or understaffed shifts.

Top Takeaways

Daily checklists prevent small problems.

Consistency comes from discipline.

Skipped checks raise safety and cost risks.

Structure beats memory under pressure.

Good managers catch issues early.

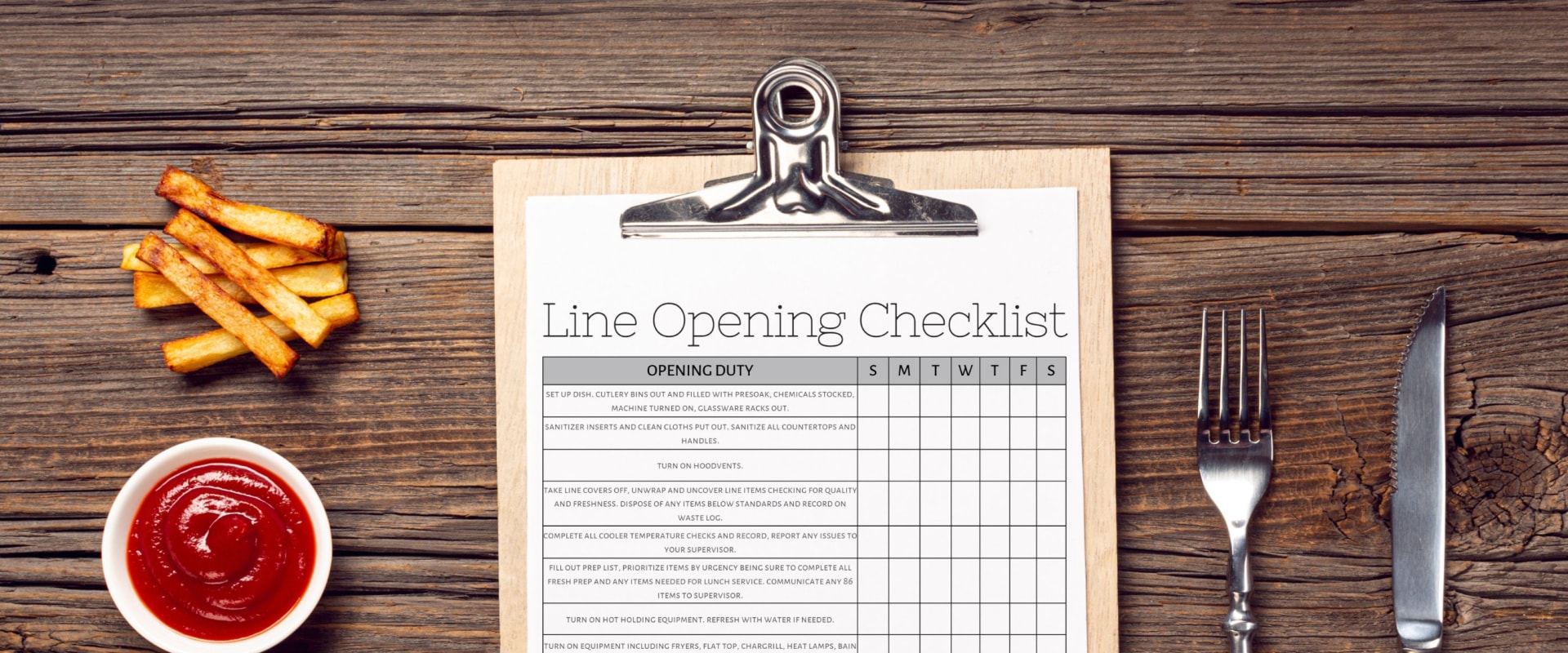

A daily kitchen management checklist exists for one reason: to keep small problems from becoming expensive ones. For restaurant managers, daily checks create structure, accountability, and consistency—especially when volume, staffing, and pressure change from shift to shift—by supporting the kitchen brigade system, confirming each station’s responsibilities, and ensuring the chain of command holds during service.

Pre-Service Kitchen Checks

Before service begins, managers should verify that the kitchen is set up to succeed. This includes confirming prep is complete, stations are stocked to par, equipment is functioning, and temperature logs are up to date. Catching gaps early prevents service slowdowns and safety issues later.

Staff Readiness & Communication

Daily management includes checking staffing coverage, clarifying station assignments, and setting expectations for the shift. Brief pre-shift communication keeps everyone aligned on menu changes, priorities, and service goals, reducing mistakes once tickets start printing.

Food Safety & Quality Control

Food safety is a daily responsibility, not an occasional task. Managers should verify proper holding temperatures, storage practices, sanitation routines, and allergen controls throughout the shift. Quality checks during service ensure food leaves the kitchen consistent with standards.

Inventory, Waste & Cost Awareness

A daily checklist helps managers spot food cost problems early. Tracking high-usage items, waste, and portion control issues on a daily basis using a food recipe costing template helps standardize portions, clarify true plate costs, and prevent inventory surprises and margin erosion at the end of the week.

Post-Service Review & Reset

After service, effective managers review what worked, what didn’t, and what needs adjustment. Cleaning, storage, prep planning for the next day, and documenting issues close the loop and set the kitchen up for the next shift.

A daily kitchen management checklist isn’t about micromanaging—it’s about creating repeatable discipline. When these checks happen every day, the kitchen becomes predictable, safer, and easier to manage under pressure.

“After managing busy kitchens, you learn that daily checklists aren’t about control—they’re about prevention. The kitchens that stay consistent are the ones that catch problems during prep, not during service, and treat daily checks as non-negotiable habits, not paperwork.”

Essential Resources

If you’re responsible for making sure a kitchen runs day in, day out, you need resources that match how real kitchens are managed—systems that work under pressure, routines that catch problems before they escalate, and checklists that keep chaos from creeping in. Below are chef-tested, operator-approved tools and guides that help you do just that.

National Restaurant Association — Back-of-House Safety Standards

Why it matters: Know the expectations kitchens are held to

Before you build systems, understand the safety and sanitation standards professional kitchens are expected to follow. This is the baseline every working chef trains to.

https://restaurant.org/education-and-resources/learning-center/food-nutrition/food-safety/

ServSafe — Kitchen Manager Food Safety Certification

Why it matters: Food safety isn’t optional—this cert proves it

ServSafe is the industry standard for food safety training. Every competent kitchen manager uses it to teach and enforce proper handling, storage, and sanitation routines.

https://www.servsafe.com/

TapTasty — Real Kitchen Management, Not Theory

Why it matters: See how daily operations actually connect

This guide breaks down staffing, station flow, inventory, and quality control as working kitchens experience them—not academic theory but real operational context.

https://www.taptasty.com/blog/kitchen-management-comprehensive-guide-to-efficiently-run-your-kitchen/

SafetyCulture — Actionable Daily Kitchen Checklists

Why it matters: Make standards repeatable every shift

Open, shift, and close checklists translate policies into daily tasks. These are the sorts of checks line cooks and managers actually run through before service begins.

https://safetyculture.com/checklists/kitchen-operations

Xenia — Daily Manager Task & Accountability Templates

Why it matters: Keep things consistent without hovering

Turn your daily responsibilities into trackable tasks. Templates and tracking tools help you delegate and verify work without watching every step.

https://www.xenia.team/templates/kitchen-manager-checklist

UpMenu — Kitchen Management Best Practices You Can Use Today

Why it matters: Practical systems that don’t overcomplicate

Covers real kitchen workflows, staff roles, and efficiency tips that match what seasoned operators expect from daily operations.

https://www.upmenu.com/blog/kitchen-management/

Restaurant365 — Inventory & Cost Control for Kitchens

Why it matters: Daily cost awareness protects your margins

Inventory control and waste reduction are daily habits, not occasional tasks. This guide shows you how to track stock, reduce waste, and protect food cost in real kitchens.

https://www.restaurant365.com/blog/restaurant-inventory-management-guide/

Together, these resources support a disciplined, day-to-day approach to kitchen operations where safety, cost control, and accountability are reinforced through the kitchen brigade, ensuring every station, role, and checklist works together to keep the kitchen running smoothly under pressure.

Supporting Statistics

Daily kitchen management checklists exist to control risks that build quietly over time.

Food safety failures start with missed routines

CDC estimates 48 million foodborne illnesses each year in the U.S.

128,000 hospitalizations and 3,000 deaths annually.

Missed temperature checks and sanitation habits are usually the cause—not rare events.

Source: https://www.cdc.gov/food-safety/data-research/facts-stats/index.html

Food waste grows when it isn’t checked daily

USDA reports 30–40% of the U.S. food supply is wasted.

In kitchens, waste often comes from over-prep, poor rotation, and loose portioning.

Daily parts and waste checks stop small losses from compounding.

Source: https://www.usda.gov/about-food/food-safety/food-loss-and-waste

Turnover makes daily verification essential

BLS shows a 4.8% quits rate in Accommodation and Food Services.

Staffing changes are constant.

Daily checklists keep standards consistent when people change.

Source: https://www.bls.gov/news.release/jolts.t04.htm

Waste reduction is a national priority

EPA confirms 30–40% of food in the U.S. is never eaten.

Waste control depends on daily receiving, storage, and prep accuracy.

Source: https://www.epa.gov/sustainable-management-food/united-states-2030-food-loss-and-waste-reduction-goal

Key takeaway:

Daily kitchen checklists prevent slow breakdowns. They protect food safety, costs, and consistency—one shift at a time.

Final Thought & Opinion

Daily kitchen checklists aren’t paperwork. They’re protected.

From firsthand experience, the kitchens that stay consistent aren’t better staffed or luckier. They’re disciplined about checking the same critical details every shift.

What daily checklists actually prevent:

Slow drops in food quality

Missed food safety habits

Rising food costs

Standards slipping on busy nights

In real kitchens, problems don’t appear overnight. They build when checks are skipped and fixes get postponed.

Final perspective:

If a kitchen only runs well with the “right” people on shift, it isn’t managed yet.

Checklists replace memory with structure.

Good managers don’t chase problems—they catch them early.

A daily kitchen management checklist is one of the simplest tools that consistently works under pressure.

FAQ on Restaurant Kitchen Management

Q: What does restaurant kitchen management mean day to day?

A: It means controlling prep, staff execution, food safety, and costs so the kitchen runs consistently even under pressure.

Q: Why do experienced managers still rely on daily checklists?

A: Because memory fails during busy service. Daily checklists catch small issues early and prevent problems instead of reacting to them later.

Q: What are the non-negotiables on a daily kitchen checklist?

A: Prep and station readiness, temperature and sanitation checks, staff coverage and communication, inventory awareness, and a proper close that sets up the next shift.

Q: How do checklists improve consistency?

A: They turn standards into habits. When the same checks happen every shift, quality and safety stay stable even as staff changes.

Q: Can a kitchen run long-term without daily management checks?

A: Only briefly. Kitchens without daily verification drift over time, and problems usually surface when they are already expensive to fix.